GESTEC

Characteristics

GESTEC is a plasticizing powder additive for plaster, which optimizes its preparation and application, prolonging the application time, increasing pullout resistance and providing greater resistance to water penetration into the mass, in addition to having an additive anti-rust in its composition. It increases productivity, eliminates waste and keeps the work site clean.

The PLASTER with the addition of GESTEC provides a soft, pasty, homogeneous mass, without lumps, characteristics that were previously only found in running mass and acrylic masses. Easy to use, it makes the plaster mass very light to handle and allows quick preparation: in less than 3 minutes the mass is already mixed and ready to start the work.

Benefits

- It provides a soft, pasty and homogeneous mass without lumps, characteristics previously only found in slurry and acrylics. It makes the plaster mass very light to handle;

- It replaces slurry, cementitious and other similar materials;

- Dispenses with slurry to finish the painting;

- Allows the application in thin layers identical to the slurry;

- Because it has a white finish, it is easy to cover with paint;

- Allows for a polished finish;

- GESTEC gives plaster greater resistance to water penetration, greater than traditional plaster;

- Provides a coating with thermal and acoustic characteristics;

- Allows rustic application and subsequent manual or mechanized sanding;

- Allows application in a single coat;

- Allows application in several thin or thick layers as a plaster;

- Application performance. Coats can be applied every 2 hours;

- Allows quick preparation of plaster powder, being ready in less than 3 minutes;

- Allows the start of work in much less time than the wait to stitch in traditional preparation;

- Any quantity can be quickly mixed, which facilitates the start and end of the work shift;

- It also facilitates the completion of the areas being applied, resulting in greater daily productivity;

- Reduces water consumption in preparation by approximately 25%;

- Generates zero material waste and consequently generating savings with 100% utilization;

- Eliminates waste disposal costs that can reach 10% to 15% generated in the traditional application system;

- The GESTEC additive for gypsum preparation with a mechanical stirrer allows the addition of aggregates such as sand, ground rubber, vermiculite, ground EPS and other materials with fine or medium granulometries, without changing the method of mechanical preparation and application of the gypsum, which significantly reduces the plastering cost;

- Allows the addition of ground rubber to avoid cracks in the application on EPS walls;

- Allows application in up to 1:30 hours after preparation;

- Replaces plaster glue, DRYWALL joint treatment tape pastes with savings of more than 50% in material cost;

- Used to glue moldings, moldings and plasterboard;

- Increases the pull-out tensile strength, with values above the average required by NBR 16575/17;

- Higher yield per kilo of gypsum as it is a lighter material;

- By having an anti-rust additive in its composition, it prevents the oxidation of the iron present in the structures during the application of the plaster, eliminating the rust stains.

Use

Plasticizing Additive for Plaster.

The gypsum mass resulting from the combination of gypsum powder + GESTEC is indicated for:

- Make the plaster. While cement plaster requires the overlapping of two or three layers until completion, the plaster mass can be placed in a single step, reducing the cost of application and achieving greater speed and practicality in execution.

- Coatings, providing a final finish ready to be painted, eliminating the need for slurry.

- Application on surfaces, walls and ceilings of:

- Masonry;

- Exposed concrete;

- Drywall;

- Fiber cement boards;

- EPS;

- Blocks.

- Manufacture and collage of:

- Cobogos;

- Plates;

- Moldings;

- Sancas;

- Columns;

- Mosaics;

- Decorative pieces.

- Treatment of joints em:

- Cardboard gesso;

- Plates;

- Moldings;

- Foundation plates.

- Substitute:

- Spackling;

- Quick drywall mass burned;

- Gesso glue;

- Reboco;

- Cementitious masses.

- Effects application:

- Decorative;

- Smooth;

- Textures;

- Rustic.

Composition

Mineral loads and special additives.

Performance

Storage

It must be kept at room temperature, in a dry and sanded place, on platforms.

Shelf life

In its original unbroken packaging, it is valid for 24 months.

Packaging

The product is sold in 5 kg packages and in three versions:

– GESTEC 30: Additive intended for the preparation of plaster for application in the traditional system, where a shorter open time is required. Allows the mixture to remain pasty and applicable for a period of up to 45 minutes, depending on the type and brand of plaster.

– GESTEC 90: Additive intended for the preparation of plaster for application in the mortar system, cementitious or similar, where a longer open time is required. Allows the mixture to remain pasty and applicable for a period of up to 90 minutes, depending on the type and brand of plaster.

– GESTEC PRO: Additive intended for the preparation of plaster for application with spraying machines. Allows the mixture to remain pasty and applicable for a period of up to 90 minutes, depending on the type and brand of plaster.

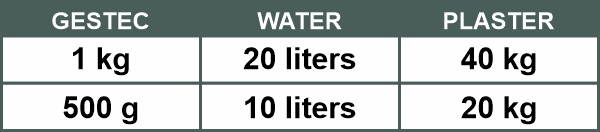

Product preparation

Add the necessary amount of water to prepare the plaster in a clean container, add the GESTEC additive and mix. Place 80% of the plaster, mix with a mechanical stirrer, then add the rest of the plaster. Mix again to disperse and make the dough pasty, homogeneous, without lumps, ideal for application. After starting the preparation of the dough, if necessary, adjust the consistency with powdered plaster and never add water.

Application

Apply the plaster added with GESTEC normally as in the traditional system. It can also be applied manually as with slurry. The composition and characteristics of the plaster may vary depending on the manufacturer. It is recommended to carry out preliminary tests using GESTEC under the same conditions as the work, to determine the desired results, as well as their compatibility with the plaster to be used.

Cleaning

Equipment and tools can be cleaned with water as long as the product is not dry. After drying, clean the tools mechanically.

ALL RIGHTS RESERVED | SELAMIX IMPERMEABILIZANTES – CNPJ 80.695.372/0001-19