ARGAMASSA PISCINA AUTOFUGANTE

Characteristics

ARGAMASSA PISCINA AUTOFUGANTE was developed for the purpose of simultaneously laying and grouting tiles, ceramic coatings, medium and large format porcelain tiles, and natural stone. It has high adherence and resistance, odorless and non-toxic product. It can be applied indoors and outdoors. Meets the requirements of ABNT NBR14992 and NBR 14081 standards.

Use

It can be used for simultaneous laying and grouting of tiles, tiles, ceramic floors and coverings, medium and large format porcelain tiles, and natural stone. Indicated for application in swimming pools, tanks, water mirrors and cold areas: bathrooms, kitchens and service areas. Indoors or outdoors. The tablets must have a minimum dimension of 2×2 cm and a maximum of 15×15 cm. ARGAMASSA PISCINA AUTOFUGANTE can also be used to apply a waterproofing layer in swimming pools and water features, and for this purpose it is applied in layers and with a final thickness of 5mm.

Not suitable for

Installation on metal, wood, fiberglass and paint, or for installing wood, metal or plastic inserts. Also, do not use it for laying coatings that have transversal deformation > 0.6 mm/m or that do not comply with the respective standards for these products.

Composition

Portland cement, selected mineral fillers and special additives.

Color

ARGAMASSA PISCINA AUTOFUGANTE is supplied in Ice White.

Performance

El rendimiento es de aproximadamente 6 Kg/m² cuando se utiliza para la colocación y el rejuntado simultáneos. Las cantidades pueden variar según la forma de las piezas a colocar, la regularidad de la superficie a revestir y el tipo de aplicación de la lechada a utilizar.

Storage

It must be kept at room temperature, in a dry and ventilated place, on pallets.

Shelf life

ARGAMASSA PISCINA AUTOFUGANTE is valid for 24 months, in its original closed packaging.

Packaging

ARGAMASSA PISCINA AUTOFUGANTE is supplied in 18 kg plastic packages

Surface preparation

The surface must be firm and in good condition, level, clean, free of dust, grease, fungus, mold, mildew, loose particles or any other contamination that could prevent the mortar from anchoring to the substrate. Before starting the laying, the preparation of the base and the execution of the joints must comply with the standards of ABNT NBR 7200, NBR 13749, NBR13753 and NBR 13754. Subfloors, renders or plaster must be at least 14 days old. Level, plumb, waterproofing, cracks, falling and resistance problems must be corrected 72 hours before laying. If you have a problem with rising damp, you must first waterproof it with the ARGAMASSA PISCINA AUTOFUGANTE by applying the mortar in at least two layers with a minimum total thickness of 5mm. Do not apply ARGAMASSA PISCINA AUTOFUGANTE directly on materials with a surface or layer containing petroleum derivatives, such as: paints, varnishes, asphalt emulsion, asphalt blanket, glue, waterproofing products based on resins and others, in which case 100% of them must be removed. of the entire area to be applied. In extreme conditions such as places exposed to the sun, high temperatures, low relative humidity, intense wind, very absorbent bases, it is necessary to moisten the base, but be careful not to soak them, in order to guarantee the adherence of the product. If there are pieces of aluminum and untreated metal on site, they must be protected as they can stain when in contact with the mortar.

Parts preparation

Las piezas deben estar secas, limpias, libres de polvo, engobes o partículas que impidan la adherencia del mortero adhesivo. Quitar el exceso de polvo de la parte trasera de la pieza (engobe), utilizando agua y un cepillo y esperar a que se seque. No sumerja los materiales a aplicar en agua antes de la colocación.

Product preparation

In a clean container, dilute 18 kg of ARGAMASSA PISCINA AUTOFUGANTE in 4 liters of clean water. Mix with a mechanical stirrer for 5 minutes until obtaining a mass of homogeneous consistency, without lumps, pasty and adherent. Leave to rest for 10 minutes, mix again and start the application. Use the product within a maximum of 1 hour after preparation.

Application

The application must be carried out at an ambient temperature between 10 and 30 °C.

With the smooth side of the trowel, apply a layer of mortar from 3 to 8 mm on the base, in areas that correspond to the laying of 3 to 4 tiles or 1 piece of ceramic tile at a time. Then pass the notched side of the trowel at an angle of approximately 60° forming continuous and uniform cords. Follow all the recommendations of tile manufacturers, ceramic tiles, porcelain tiles and natural stones. For ceramic, porcelain or natural stone coverings with an area greater than 900 cm², apply the mortar on the surface to be applied and also on the back of the piece (double bonding).

Laying of screened, single or glued-in tablets

Place the tablets on the fresh mortar cords. For better fixing and leveling, it is recommended to use a flat piece of wood. Place this wood over the inserts and tap lightly with a rubber mallet, pressing the inserts evenly until the cords are crushed. Then, after laying the tile, apply the same mortar prepared for grouting. Use a rubber trowel.

Laying of paper-bonded inserts

With the smooth side of the trowel, apply the mortar on the back of the tiles, completely filling all the joints between the tiles. Place the tablets on the fresh mortar cords. For better fixing and leveling, it is recommended to use a flat piece of wood. Place this wood over the inserts and tap lightly with a rubber mallet, pressing the inserts evenly until the cords are crushed. Wait approximately 1 hour (or the time necessary for the mortar to appear semi-hardened) and remove the paper from the tablets according to the manufacturer’s recommendation. Check that all tablets are perfectly adhered, as when removing the paper some tablets may move and lose adherence. With the aid of a rubber trowel, make the necessary touches to correct possible flaws that may occur with the removal of the paper. During laying, remove some pieces just placed and check if the back of the piece is covered with mortar. Wait between 40 and 60 minutes to finish, using a soft, clean and slightly damp sponge. Always use clean water to moisten the sponge, this will prevent stains on the joints between the tablets.

Grouting

Carry out the grouting using the Autofugante Swimming Pool Mortar with the aid of a rubber trowel, pressing with continuous movements into the joints until they are completely filled. Remove excess product on the surfaces of the parts. Wait between 40 and 60 minutes after application (when the grout is in a semi-hardened state) before finishing, using a soft, clean and slightly damp sponge. Always use clean water to moisten the sponge, this will prevent stains on the joints. During laying and grouting, do not contaminate the application with foreign materials to avoid stains and contamination in the grout. For cleaning, use a clean, damp cloth before the mortar dries. Protect the applied area with canvas for at least 72 hours, to prevent direct sunlight or rainwater from entering. After this period, the area can be released for light traffic of people. For post-construction cleaning, wait 3 days. Daily cleaning can be started 15 days after installation, using water and neutral soap, and then the area should be rinsed thoroughly with water.

Important

In swimming pools and other reservoirs, wait 15 days after laying and grouting to fill the applied areas with water. To avoid premature wear of the grout, keep the water in the pool, water mirror or tank properly treated using good quality products. It is also extremely important to maintain the calcium hardness of the water at adequate levels, because if it is at low levels, corrosion of the grouts may occur and when it is at high levels, calcium incrustations may occur.

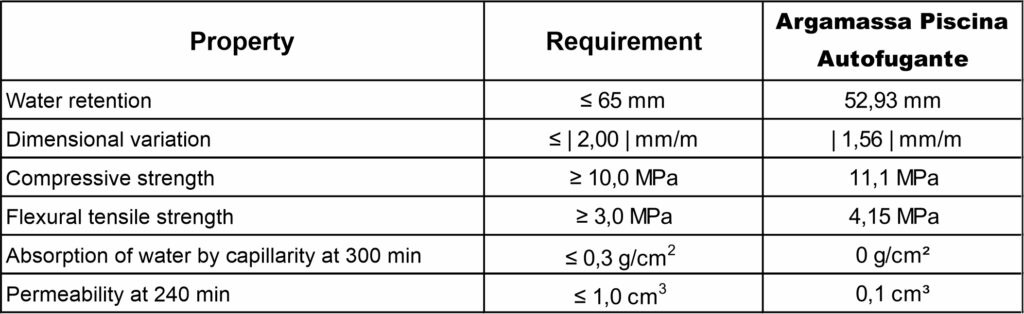

Properties and characteristics

ARGAMASSA PISCINA AUTOFUGANTE meets the following requirements of the standard below:

Type II grout mortar, according to ABNT NBR 14992.

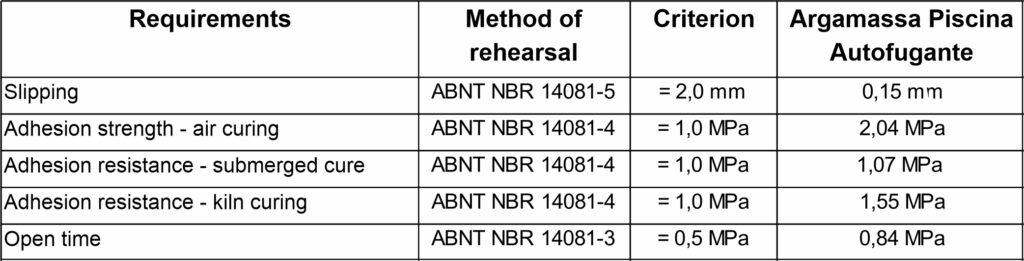

ARGAMASSA PISCINA AUTOFUGANTE meets the requirements of ABNT NBR 14081-1 for ACIII mortar, being classified as ACIII-E/D.

Cleaning

Equipment and tools can be cleaned with water while the product is not dry. After drying, clean the tools mechanically.

ALL RIGHTS RESERVED | SELAMIX IMPERMEABILIZANTES – CNPJ 80.695.372/0001-19